As technology advances, so does modern tools such as pill press machines. For those who are new to this type of machinery, it is important to understand the common mistakes and risks associated with using them to avoid any potential problems. At Tabletbindertdp.com, we provide comprehensive guidance on properly operating a pill press machine and what safeguards should be taken when using one. Here are some tips for avoiding common mistakes and risks when using a pill press machine.

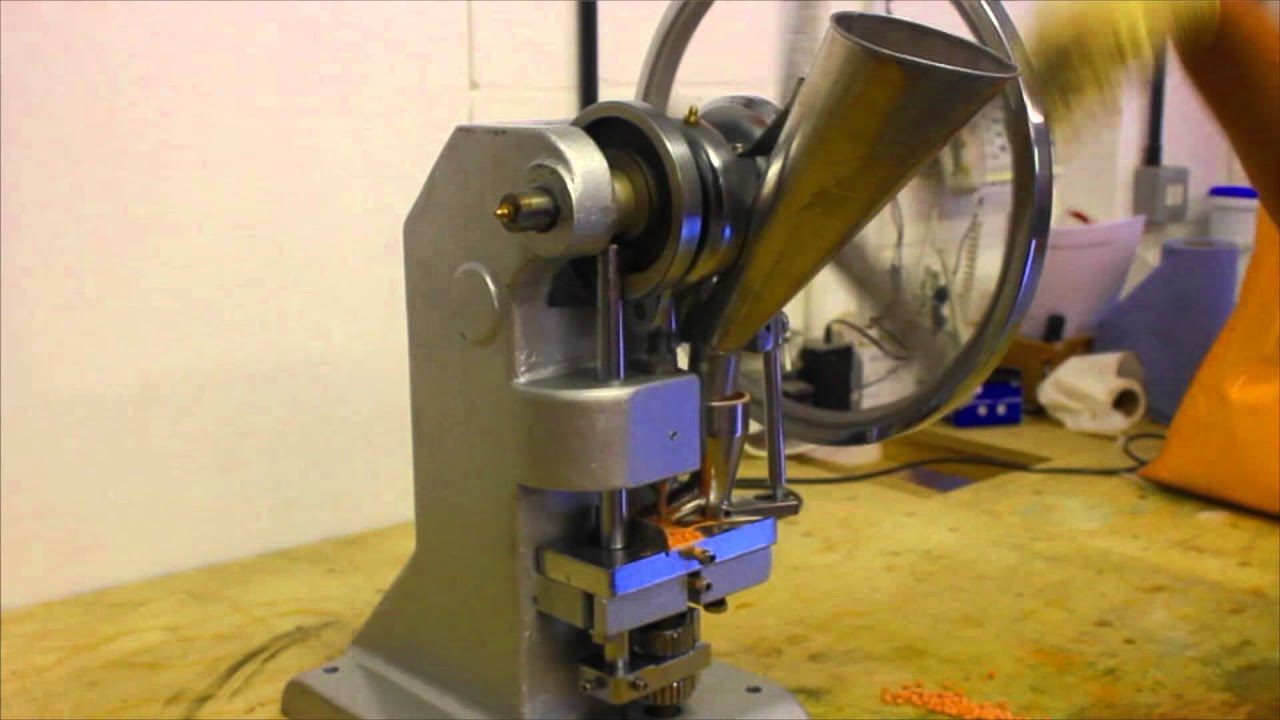

1: Understand How the Pill Press Machine Works

The first step in avoiding common mistakes and risks when using a pill press machine is understanding exactly how it works. Before attempting to operate the equipment, read through all instructions carefully and ensure you know all safety protocols that must be followed while operating the machine. Please familiarise yourself with all parts of the machine and become knowledgeable with its operation before beginning use. Taking time to thoroughly understand how the machine operates will save you from making potentially costly mistakes later on.

2: Wear Appropriate Safety Gear

When working with any machinery, safety should always be your number one priority. You must wear protective gear such as safety glasses, gloves, steel-toed shoes, long pants and sleeves when operating a pill press machine to protect yourself from potential harm like cuts or burns caused by flying debris or hot surfaces during operation. Ensure you also have proper ventilation if working indoors; otherwise, fumes may build up, causing health issues over time.

3: Ensure proper setup

Before starting any work on the tablet press machine, ensure that everything is set up correctly according to the manufacturer’s guidelines, including power supply voltage specifications and other detailed instructions found in either the user manuals or online tutorials available at tabletbindertdp.com. Ensuring everything is set up correctly will help prevent errors due to improper installation, which can have disastrous consequences such as damage to components or even injury while operating the machine.

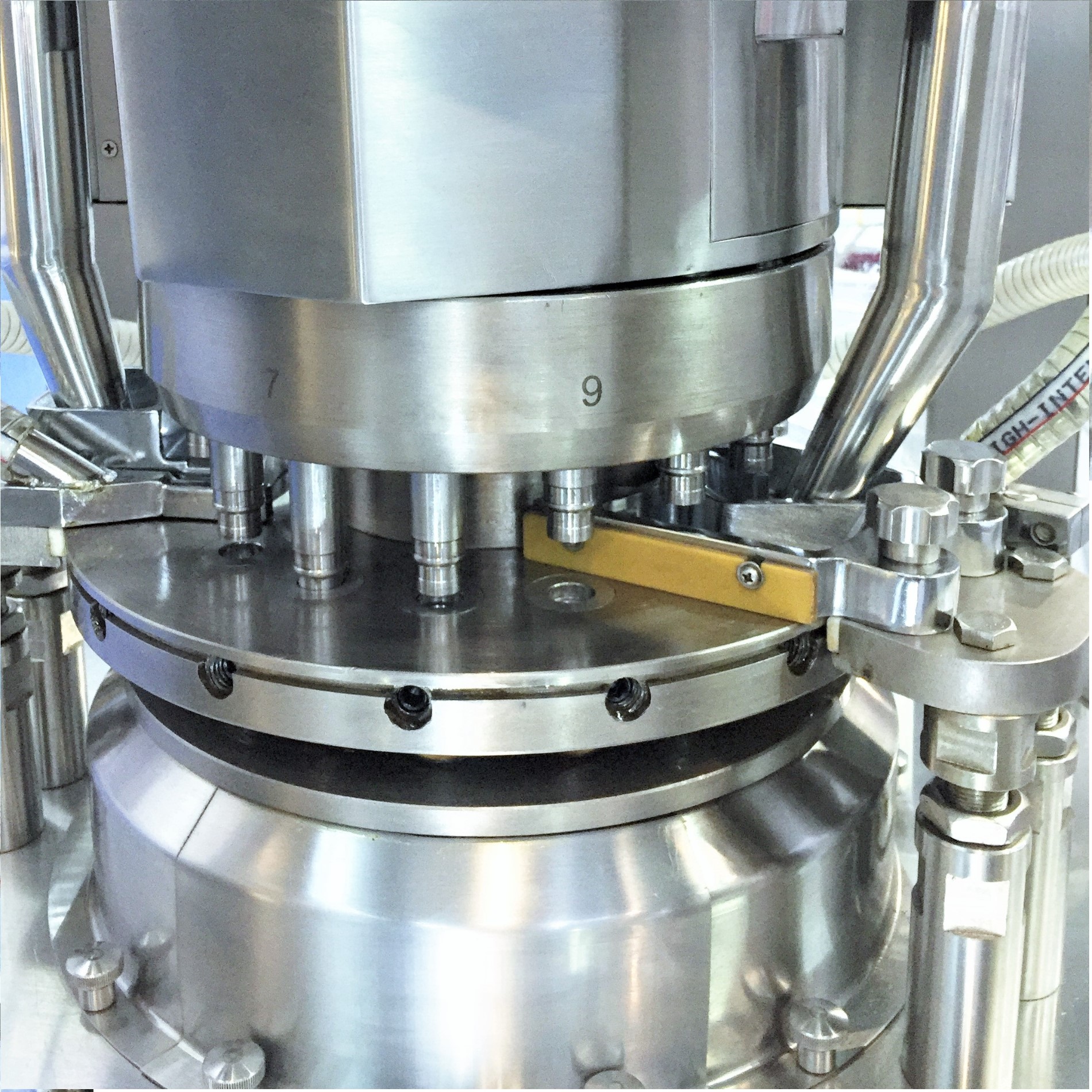

4: Check all components regularly

In addition to correctly setting up the cushion press before starting work, it is also important to regularly check all components for signs of damage or wear after each session of use, especially if the same equipment has been used repeatedly over a long period, as unexpected malfunctions can occur due to fatigue or corrosion, which can lead not only to expensive repair costs but also to dangerous accidents if not monitored closely enough.

5: Choose high quality materials

Another factor to consider when using a tablet press machine is the quality of the materials used for production purposes, as poor quality raw materials can contribute greatly to the production of poor quality tablets, which can lead not only to wasted effort, but also to dangerous results depending on the intended application after tablet formation, such as pharmaceuticals, where inferior products can endanger the health of end users when consumed.

6: Use experienced operators

Using experienced operators to carry out tablet pressing operations has huge advantages over less experienced personnel, as they have better judgement gained from years of performing similar tasks, giving them greater insight to identify potential risks in advance, leading to safer outcomes overall.

7: Have contingency plans in place

In the event that something does go wrong during operations, which can range from minor technical problems with electrical systems to serious injuries resulting from the mishandling of high-powered equipment, emergency plans need to be in place in advance, with detailed steps outlining various scenarios and corresponding action plans, allowing for faster response times if required.

8: Use automated systems where possible

In today’s digital age, advances in technology mean that automated systems can now perform many functions that were previously done manually, including aspects directly related to the pill-forming process, where programmed machines replace human labour, offering increased accuracy, speed and significant cost savings, while significantly reducing the risk of error; thus providing a much safer environment for all involved.

Using these simple tips will go a long way in helping anyone stay safe while using their own personal pill press machines at home or commercially within industrial settings alike – ensuring maximum efficiency without compromising operator safety too much along the way. For more information on how best to approach this subject, please visit www.tabletbindertdp.com today!